The substrate 101 may comprise a high-lifetime N-type single crystalline silicon wafer. 1, a thin dielectric layer 102 is formed on a single crystalline silicon substrate 101. 1-12 show cross-sections that schematically illustrate a method of manufacturing a solar cell in accordance with an embodiment of the present invention. In other instances, well-known details are not shown or described to avoid obscuring aspects of the invention.įIGS. Persons of ordinary skill in the art will recognize, however, that the invention can be practiced without one or more of the specific details. In the present disclosure, numerous specific details are provided, such as examples of apparatus, process steps, and structures, to provide a thorough understanding of embodiments of the invention. 13 shows a flow diagram of a method of manufacturing a solar cell in accordance with an embodiment of the present invention. 1-12 show cross-sections that schematically illustrate a method of manufacturing a solar cell in accordance with an embodiment of the present invention.įIG. BRIEF DESCRIPTION OF THE DRAWINGSĪ more complete understanding of the subject matter may be derived by referring to the detailed description and claims when considered in conjunction with the following figures, wherein like reference numbers refer to similar elements throughout the figures. These and other features of the present invention will be readily apparent to persons of ordinary skill in the art upon reading the entirety of this disclosure, which includes the accompanying drawings and claims. The solar cell includes contact holes that allow metal contacts to connect to corresponding emitters.

The other emitter of the solar cell may be formed in the single crystalline silicon substrate and comprise doped single crystalline silicon.

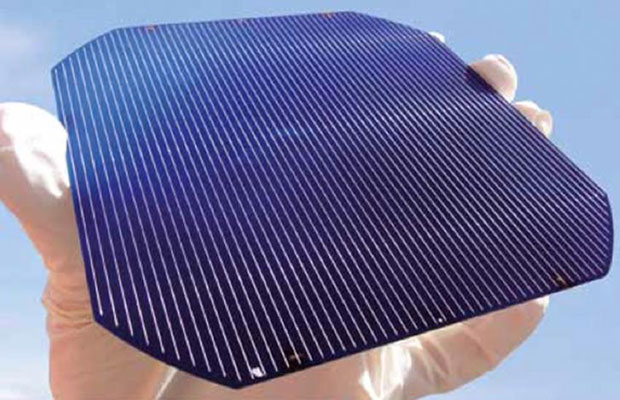

One emitter of the solar cell may comprise doped polycrystalline silicon that is formed on the thin dielectric layer. The thin dielectric layer may comprise silicon dioxide that is formed directly on the backside surface of the single crystalline silicon substrate. The solar cell may have a thin dielectric layer formed on a backside surface of a single crystalline silicon substrate. In one embodiment, an all back contact solar cell has a hybrid emitter design. Embodiments of the present invention pertain to a hybrid emitter design that simplifies the manufacture of solar cells while retaining efficiency. To remain a commercially-viable renewable energy source, solar cells need to be manufactured at low cost. An external electrical circuit, e.g., a load, may be connected to the metal contacts to be powered by the solar cell. In an all back contact solar cell, all metal contacts and corresponding emitters are formed on the backside of the solar cell. A solar cell has a front side that faces the sun during normal operation to collect solar radiation and a backside opposite the front side. Solar cells are well known devices for converting solar radiation to electrical energy. More particularly, embodiments of the subject matter relate to solar cell fabrication processes and structures. TECHNICAL FIELDĮmbodiments of the subject matter described herein relate generally to solar cells. The Government may have certain rights in the invention. The invention described herein was made with Governmental support under contract number DE-FC36-07GO17043 awarded by the United States Department of Energy. STATEMENT REGARDING FEDERALLY SPONSORED RESEARCH OR DEVELOPMENT 19, 2012, which is incorporated herein by reference in its entirety.

0 kommentar(er)

0 kommentar(er)